PART 1, PART 2, and PART 3 of our series are important information to have before diving into the final section on Storage Management.

We invite you to take a few minutes an catch up before reading this last section. All of these parts create the perfect environment for any type of onion storage needs and one is not successful without the other.

Thank you for joining us on our Onion Storage Management journey, let’s get started with the last issue: Storage Management.

PRIMARY ISSUE 4:

Storage Management

In order to investigate these primary issues for successful onion storage, let’s look at it from a timetable format of logical stages for storage management. The primary issues can then be discussed as they apply to the stages:

One management item that is crucial during initial storage is moisture. This must be controlled during harvest and post-cure stages. There are at least five sources for free moisture in storage:

- Surface moisture on onions that are not dry

- Internal moisture loss from uncured onions

- Respiration

- Decay

- Condensation

The goal during harvest is simply to make certain that any surface moisture on the onions brought into storage is exhausted. Most likely, curing will be completed during heated post-cure application in storage. However, the most efficient technique to remove moisture from the storage is to use full fresh air, whenever weather permits, and as much as you’ve got.

Word of caution: During Harvest with the fresh air damper open, and without temperature control, the control system must prevent blowing supply air to the onions that has a dewpoint greater than pulp temperature. The possibility does exist that pulp temperature could drop dramatically during the night, significantly cooling the onions, followed in the morning by a warm moist weather system. If the dewpoint of supply air blown on the onions is greater than pulp temperature, condensation will form on the onions and cause severe problems.

The storage manager or control system must continually monitor onion temperature and have dewpoint control to guard against moisture condensing on the onions.

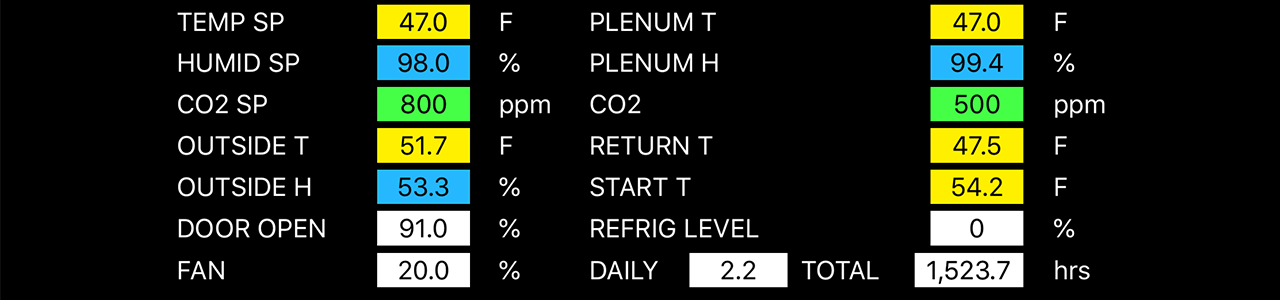

Understanding dewpoint: Use a sling psychrometer or device that measures temperature and humidity, along with a psychrometric chart to determine the dewpoint of the supply air. By comparing air dewpoint to onion pulp temperature assures one in knowing the actual situation. Being aware of the weather and pulp temp is important because the process is so inconvenient, and it almost takes no time for condensation to form. It is especially helpful to have a control panel that calculates and presents dewpoint of the supply air to the onions, along with a presentation of pile temperature, so that you know what’s really going on. A control panel with this feature can then dictate appropriate action to the system to prevent the incorrect supply air.

In addition, if the control panel records history data, the complete record of temperatures and humidities can be quickly viewed for any time during the entire storage season.

The condition of the onions at harvest dictates what the storage and system must actually have to do. If, for example, you have late-maturing onions that prevents significant field curing before harvest into storage, the system must be capable of any drying required, along with completion of the cure. The recommendation for completely curing in storage, as mentioned earlier, is at least 2 cfm per cubic foot of onions. Some recommendations for curing in storage are 3 cfm per cubic foot of onions, which equates to 160 cfm per ton!

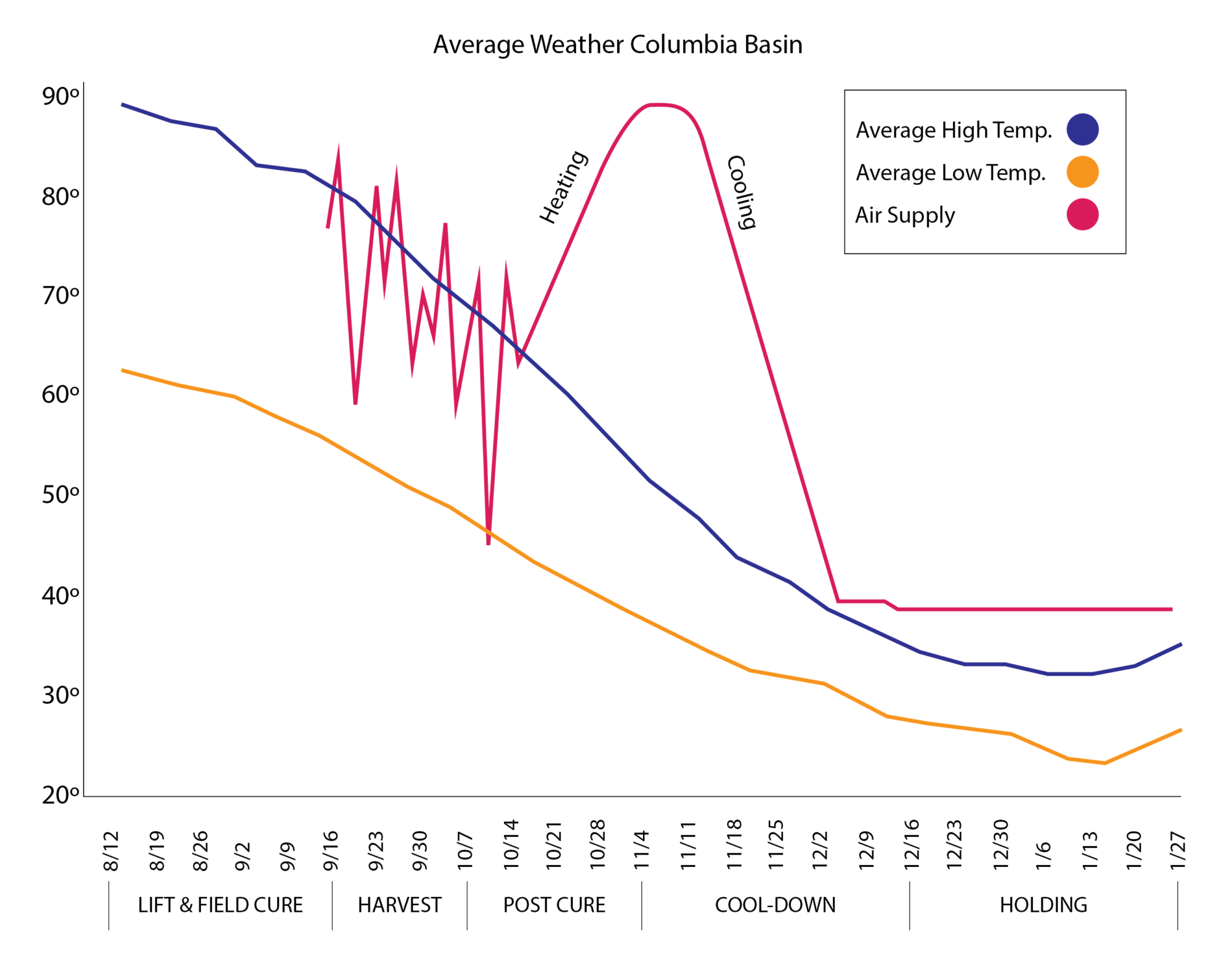

Study the example we’ve provided in figure 3 on the next page. Note that during harvest, the supply air temperature squiggles up and down because we’re purely using full fresh air with only dewpoint control to exhaust moisture from storage. The idea is to simply take advantage of the weather we actually have, using our knowledge of normal weather as a guide.

The cure is best completed as soon as the storage is filled, the doors are closed, and by raising the supply air temperature at a steady ramp rate over two – three weeks. This is done by supplemental heat and the top of the pile reaches at least 93°F. The intake fresh air door(s) must be set as open as possible, and still allow heating to take place to exhaust moist air. This heating phase accomplishes two major tasks:

- The heated air can hold more moisture and, consequently, exhaust more moisture.

- Heating the onions to between 93°F and 95°F kills the Botrytis allii fungus, and a dry neck will not support hyphal growth.

The initial supply air temperature during this heating phase should be limited to no more than 7°F higher than onion temperature at the bottom of the pile. After the initiation of the heating phase the bottom of the pile will approach supply air temperature and expect the top of the pile to lag supply air temperature by 5°F, or so.

During this curing process, it’s important to remember to not allow supply air to be too dry. Active attention to control supply air relative humidity during heating to between 60%RH and 70% RH will minimize balding, minimize shrinkage, and assist in desirable color development. In fact, supply air RH between 75%RH and 85% RH is more desirable if your system provides good control.

As mentioned before, if the supplemental heat is adequate, the heating phase should meet setpoint between two and three weeks. There is considerable “flywheel” effect with the heated pile, that is, the heated pile will tend to stay warm. Consequently, as soon as the top of the pile reaches 93°F, immediately reduce the supply air setpoint to 85°F, and program a target temperature of 39°F to be reached in about one month. Due to the heat in the pile at the start of Cool-Down, the top of the pile may reach 95°F before starting to fall. Normal weather will provide cooling from outside air for the first few weeks during cool-down. Sometimes actual temperatures can be higher or lower than the Normal Average. But the Normal Average curve will usually be an adequate guide to start with.

Since the Black Mold fungus, Aspergillus niger, is very active between about 68°F and 104°F, with relative humidity above 80%, it is especially important to control supply air relative humidity to less than 80% when the pile is above 60°F.

After the pile temperature has been reduced to 60°F, do not get in a big hurry to get to setpoint for holding unless you have refrigeration. If you cool too quickly, and your system does not have refrigeration, you could easily lose the ability to adequately control both temperature and humidity. Once the pile temperature is below 60°F any black mold that exists should not continue to propagate.

Normal Average Columbia Basin weather will allow a 39°F temperature setpoint for holding stage in a storage without refrigeration, provided the system is setup to run when cooling is available. This temperature can usually be achieved, with adequate margin, by mid December, and held reasonably constant until sometime in February. Unfortunately, foggy weather can be typical with this same holding period and requires management attention. It can be challenging to get enough run time. During this period, it’s nice to have dehumidification equipment to maintain humidity in the 60% to 70% range. It is wise to have refrigeration if colder storage temperatures are desired. It also provides some “insurance” for unusually warm weather late in the year, or even if you want to store onions until a later following year into months of June and July. In either case, refrigeration, coupled with dehumidification equipment, is necessary to get the job done no matter the direction Mother Nature decides.

Onion management can be tricky when all variables are considered. Storage management decisions must be based on the onions brought into storage, the weather, and the storage and system capability. Onion storage management does require an interested storage manager with constant attention to details. Constantly adjusting system operation as required to maximize performance. Experience with the necessary knowledge, skill, equipment, and attention to detail, will result in effective onion storage management.