Primary Issue 3

Storage & System

Today, a fully turned-out modern Suberizer onion storage designed to store typical Sweet Spanish long-day onions grown in the Columbia Basin should include the following design elements:

Storage capacity based on an onion specific weight of 37.5 #/ft3 or a specific volume of 53.33 ft3/ton

- At a pile depth of 10 – 12 feet

- The system must be designed to uniformly supply:

- A minimum of 1 cfm/ ft3 of onions (53.33 cfm/ton)

- and ideally, supply 2.25 cfm/ft3 (106.67 cfm/ton), or more.

- Supplemental heat that will provide at least 850 BTU/hr/ton of onions

- Refrigeration of at least one ton per 50 tons of onions.

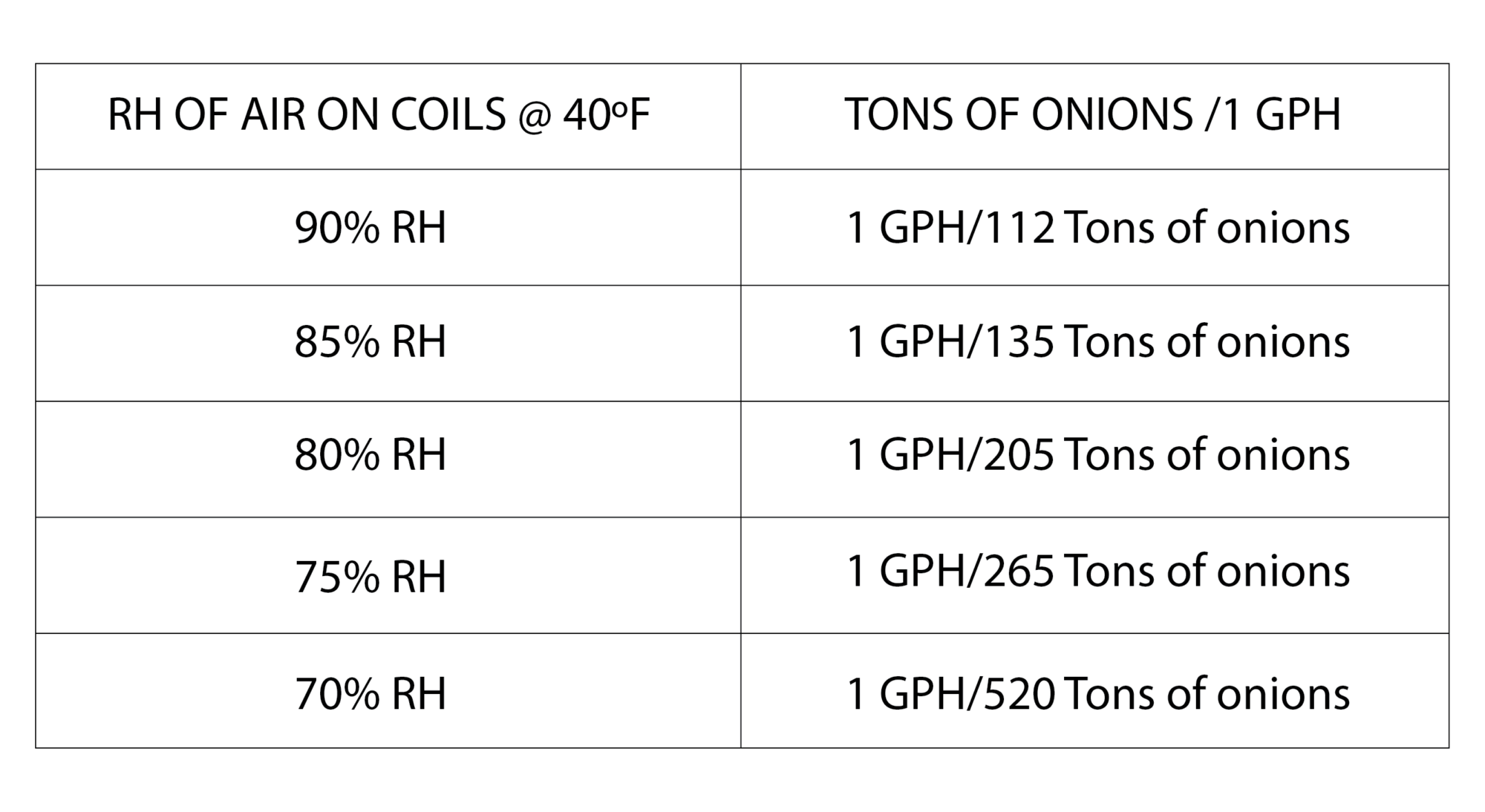

- Dehumidification equipment that will remove water at these rates:

- A Suberizer Air Everywhere Floor delivery system (instead of airpipe).

- A control system that will properly merge and automatically control Intake Supply Air, heat, refrigeration, and dehumidification equipment, and the ability manual control of each, as well.

Onions are more successfully stored in bulk than in boxes. A storage with a Suberizer Air Everywhere floor system allows storage in bulk, boxes, or a combination. It also provides significantly superior airflow through the onions.

There is so much information and variables to consider having a perfect storage and system in place for onions. Appropriate storage and system equipment are important; but in our next post we’ll discuss storage management and how it ties to Condition, Weather, and Storage.